RetaLac®

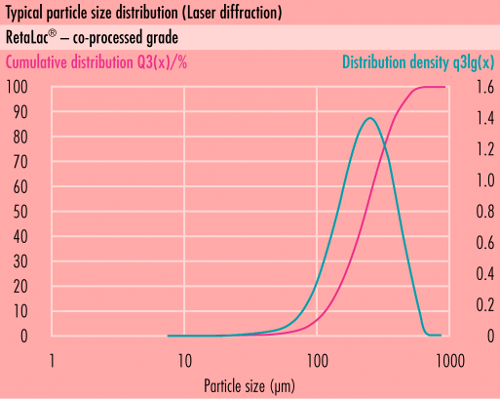

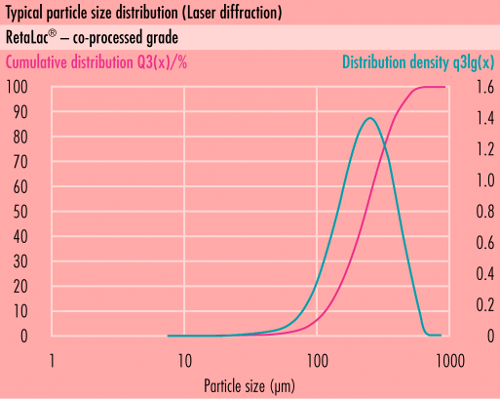

MEGGLEs co-processed excipient, RetaLac®, appears as a white, or almost white odorless powder, which is freely flowing and partially soluble in cold water. It comprises equal parts of hypromellose (type 2208, a.k.a. “K-type”) with a nominal viscosity of 4000 mPa·s, together with milled ?lpha-lactose monohydrate grade, both of compendial quality. A specialized spray-agglomeration process generates textured, highly structured particles with d50 in the range of many directly-compressible excipients, 100 µm to 200 µm, typically 125 µm.

Lactose identification is performed according to Ph. Eur. lactose monohydrate identification test method C: a red coloration appears. Verification of hypromellose is performed according to the hypromellose monograph, identification test method B, E also Ph. Eur.: a gelation of solution is detectable at >50°C.

Shelf life / Retest:

24 months

Standard Packaging:

12 kg - Plastic Drum with PE-EVOH-PE Inliner

Particle size distribution

[Mechanical sieve shaker]

- <63 µm: NMT 25%

- <250 µm: NLT 80%

Typical Values

- Bulk Density [g/l]: 340

- Tapped Density [g/l] : 460

- Hausner factor: 1.35

- Carrs index: 26.09 %

Benefits

- Direct compression of modified release formulations

- Superior processibility compared to corresponding wet granulated and physical admixture of parent ingredients

- Meets compendial requirements

- Drug release kinetics are predominantly controlled by pure diffusion

- Unaffected by acidic conditions (between pH 1 and 7)

- Dissolution can be quit

Areas of Application

- Tabletting - Direct Compression, also for multi unit and mini tablets

- Tabletting - Roller Compaction

- Preparation of aqueous HPMC-formulations

- Spheronization, Extrusion