Tablettose® 100

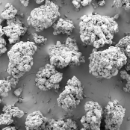

The product Tablettose® is manufactured by a continous spray agglomeration process, where water is used as the binder and is sprayed onto fluidized fine milled lactose particles, creating liquid bridges to form agglomerated lactose.

Tablettose®, especially designed for Direct-Compression, combines the flowability of coarse lactose crystals and the good compressibility of fine milled lactose.

Tablettose® 100 is produced from a smaller starting particle size than the material used for Tablettose® 80 and Tablettose® 70. As a result, Tablettose® 100 has a higher dilution potential compared to Tablettose® 70 and Tablettose® 80 due to increased compactability.

Shelf life / Retest:

24 months

Standard Packaging:

25 kg - Paper bag with PE-EVOH-PE Inliner

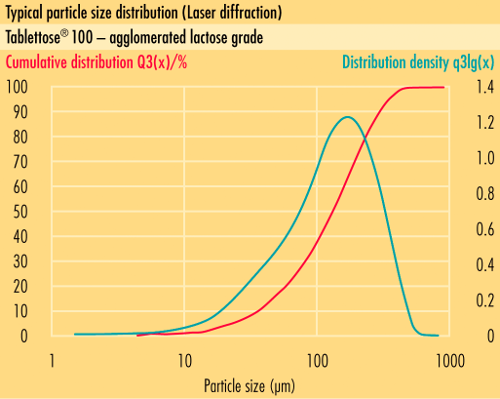

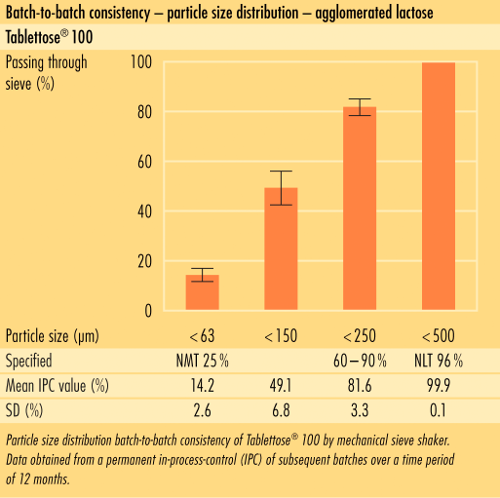

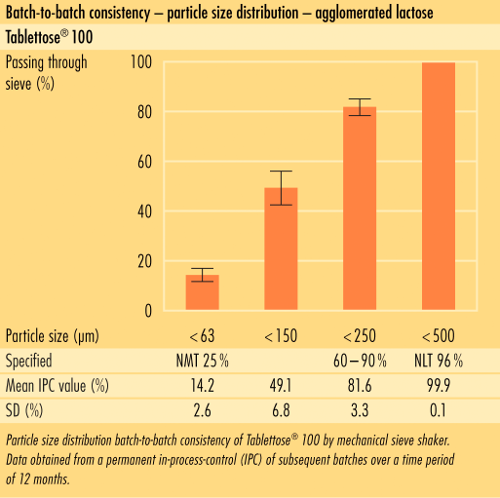

Particle size distribution

[Mechanical sieve shaker]

- <63 µm: NMT 25%

- <250 µm: 60-90%

- <500 µm: NLT 96%

Typical Values

- Bulk Density [g/l]: 580

- Tapped Density [g/l] : 720

- Hausner factor: 1.24

- Carrs index: 19.44 %

Benefits

- Very good flowability

- Very good compactability

- Low hygroscopicity

- Excellent stability

- Superior blending characteristics

- Fast disintegration times

Areas of Application

- Low dose DC formulations

- Capsule and sachet filling

- Effervescent tablets

- Artificial sweetener tablets

- Orally disintegrating tablets