Anhydrous lactose

MEGGLE has it.

The right anhydrous lactose product for direct compression

Although the majority of pharmaceutical lactose is shipped as lactose monohydrate, which is available in a variety of types such as different particle size and shape, anhydrous lactose has conquered its valued position among excipients used as filler/binder.

Part of it is its versatility, as it is used for granulation and direct compression operations alike. Anhydrous lactose is produced by roller drum drying of an aqueous lactose solution and subsequent milling. By carefully choosing the process parameters, anhydrous lactose can be obtained with desired particle size distribution (PSD) and ratio of beta (anhydrous lactose) to alpha (lactose monohydrate) lactose. Both, PSD and ratio, alter the performance of anhydrous lactose and therefore are kept consistent at MEGGLE through thorough process understanding and sound process control.

Advantage: For API’s susceptible to water

Contrary to the belief that anhydrous lactose is free of lactose monohydrate, pharmacopoeial requirements for anhydrous lactose are limited to not less than 50 % beta lactose which synonymously is used for anhydrous lactose. The total water content (determined by Karl-Fischer-analytics) of anhydrous lactose is however limited to 1.0 % which allows for not more than 20 % lactose monohydrate as part of anhydrous lactose’s composition. Regardless of the present water, anhydrous lactose is favored by scientists as valued option when dealing with active pharmaceutical ingredients, which are susceptible to water.

Anhydrous lactose: For high dosage formulations

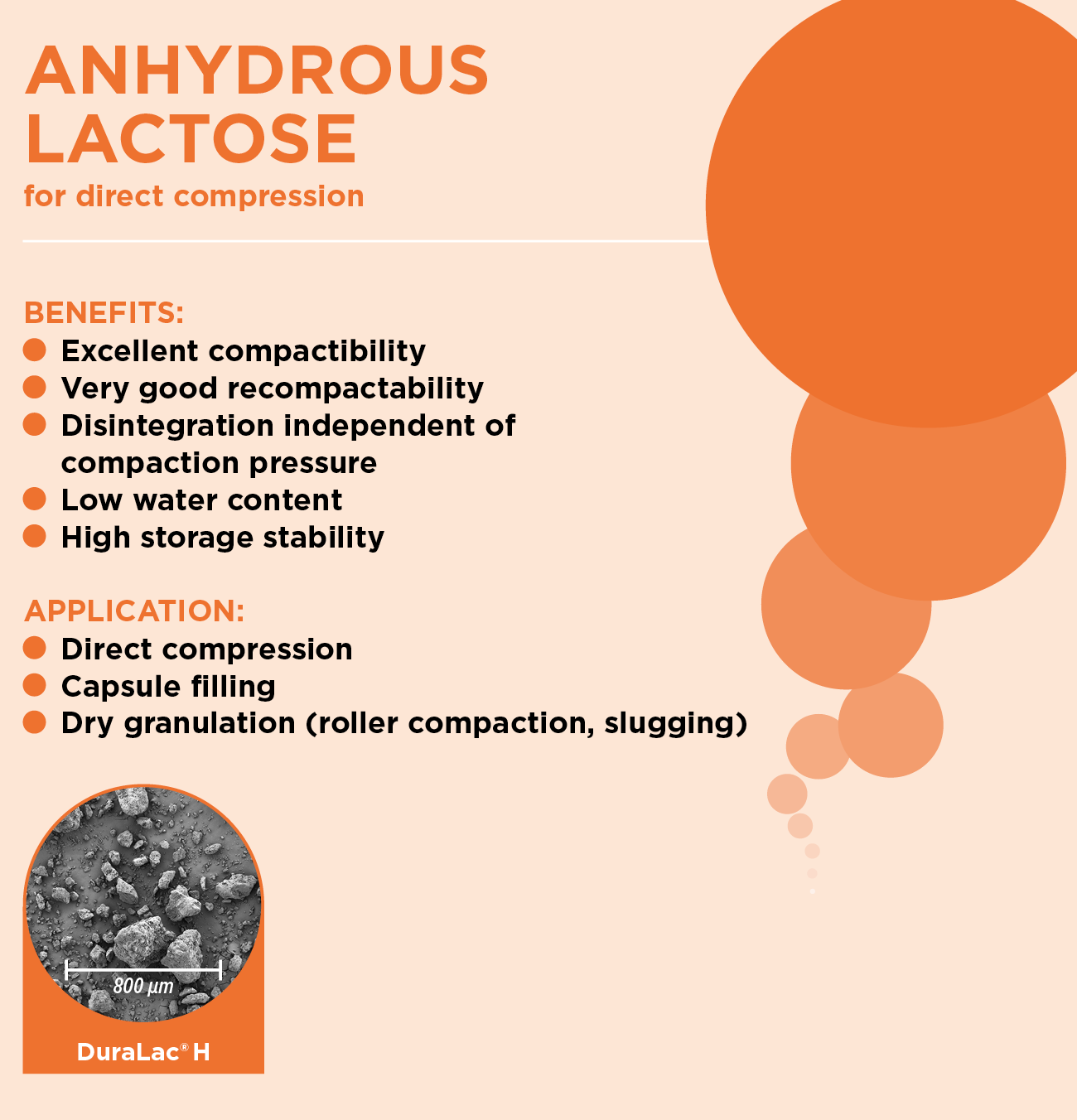

When anhydrous lactose is used in direct compression operations, its superior ability to form strong compacts enables scientists to easily develop high dosage formulations, requirements, which sometimes cannot be met by agglomerated lactose monohydrate products. Surprisingly, anhydrous lactose reportedly was being used in wet granulation operations, maintaining a fair amount of its superior compactibility, and justifying this rather unconventional move. Where anhydrous lactose arguably excels are roller compaction operations. The precompaction through the use of the roller compactor leads to a loss of material’s compactibility. Microcrystalline Cellulose (MCC), very well known for this behavior, is outperformed by anhydrous lactose, which still provides excellent compactibility, despite roller compaction treatment. In order to protect anhydrous lactose’s properties throughout its use, MEGGLE has carefully chosen a protective packaging, enabling anhydrous lactose usage throughout various environmental conditions, in particular when relative humidity is elevated.

MEGGLE´s anhydrous lactose grade for direct compression is available under the trade name

Information / Sample request:

MEGGLE has it.

The right anhydrous lactose product for direct compression

Although the majority of pharmaceutical lactose is shipped as lactose monohydrate, which is available in a variety of types such as different particle size and shape, anhydrous lactose has conquered its valued position among excipients used as filler/binder.

Part of it is its versatility, as it is used for granulation and direct compression operations alike. Anhydrous lactose is produced by roller drum drying of an aqueous lactose solution and subsequent milling. By carefully choosing the process parameters, anhydrous lactose can be obtained with desired particle size distribution (PSD) and ratio of beta (anhydrous lactose) to alpha (lactose monohydrate) lactose. Both, PSD and ratio, alter the performance of anhydrous lactose and therefore are kept consistent at MEGGLE through thorough process understanding and sound process control.

Advantage: For API’s susceptible to water

Contrary to the belief that anhydrous lactose is free of lactose monohydrate, pharmacopoeial requirements for anhydrous lactose are limited to not less than 50 % beta lactose which synonymously is used for anhydrous lactose. The total water content (determined by Karl-Fischer-analytics) of anhydrous lactose is however limited to 1.0 % which allows for not more than 20 % lactose monohydrate as part of anhydrous lactose’s composition. Regardless of the present water, anhydrous lactose is favored by scientists as valued option when dealing with active pharmaceutical ingredients, which are susceptible to water.

Anhydrous lactose: For high dosage formulations

When anhydrous lactose is used in direct compression operations, its superior ability to form strong compacts enables scientists to easily develop high dosage formulations, requirements, which sometimes cannot be met by agglomerated lactose monohydrate products. Surprisingly, anhydrous lactose reportedly was being used in wet granulation operations, maintaining a fair amount of its superior compactibility, and justifying this rather unconventional move. Where anhydrous lactose arguably excels are roller compaction operations. The precompaction through the use of the roller compactor leads to a loss of material’s compactibility. Microcrystalline Cellulose (MCC), very well known for this behavior, is outperformed by anhydrous lactose, which still provides excellent compactibility, despite roller compaction treatment. In order to protect anhydrous lactose’s properties throughout its use, MEGGLE has carefully chosen a protective packaging, enabling anhydrous lactose usage throughout various environmental conditions, in particular when relative humidity is elevated.

MEGGLE´s anhydrous lactose grade for direct compression is available under the trade name