FlowLac® 90

The product FlowLac® is produced by spray-drying a suspension of fine milled alpha-lactose monohydrate crystals in a solution of lactose. When lactose in solution is spray-dried, a rapid removal of water is taking place, whereby amorphous, non-crystalline lactose is formed in addition to crystalline lactose. Based on the amorphous content, kept on a stable level, non-varying better tabletting properties can be reached.

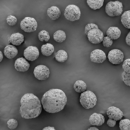

Due to the spray-drying process, FlowLac® has a spherical agglomerate shape, consisting of small alpha-lactose monohydrate crystals bound by amorphous lactose.

FlowLac® 90 was developed to provide greater compactability compared to FlowLac®100 by optimizing the amorphous lactose content. In addition, the particle size distribution makes FlowLac® 90 virtually dust-free.

Shelf life / Retest:

36 months

Standard Packaging:

25 kg - Carton box with aluminium laminated inliner

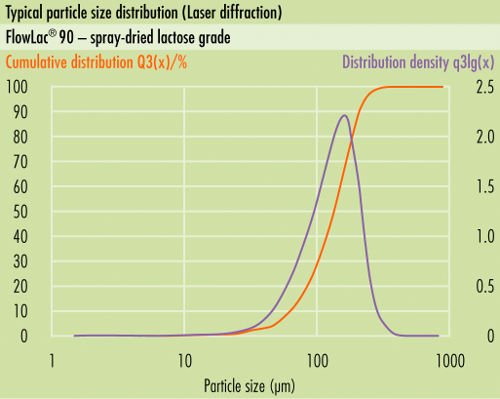

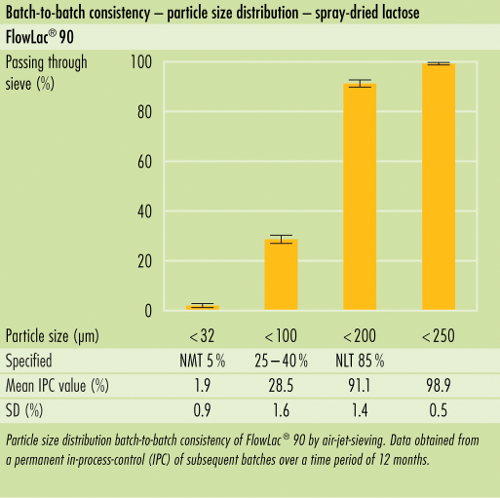

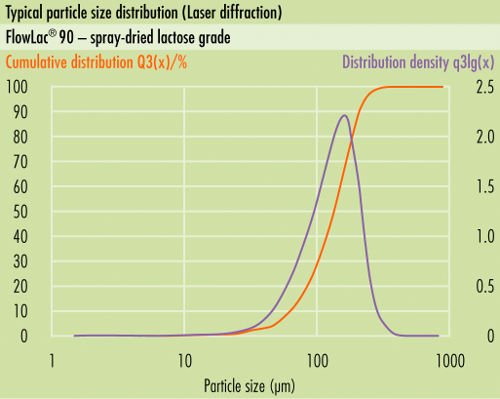

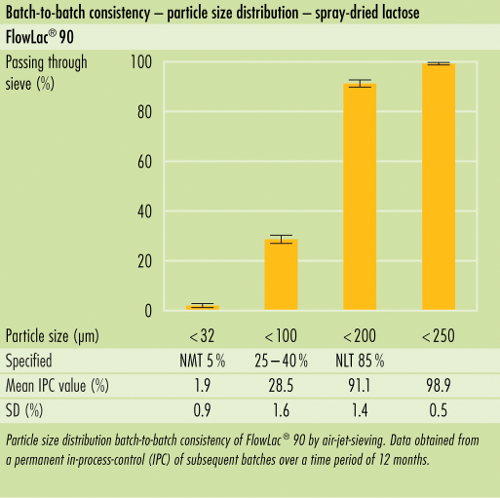

Particle size distribution

[Air jet sieve]

- <32 µm: NMT 5%

- <100 µm: 25-40%

- <200 µm: NLT 85%

Typical Values

- Bulk Density [g/l]: 560

- Tapped Density [g/l] : 670

- Hausner factor: 1.2

- Carrs index: 16.42 %

Benefits

- Superior flowability

- Excellent compactability

- Low hygroscopicity and high stability

- Fast disintegration times

Areas of Application

- Low to medium dose DC formulations

- Formulations with poorly flowing API´s

- Capsule and sachet filling